Durafosf plus

is a treatment that drastically lowers

the friction coefficient

of two connecting surfaces

DURAFOSF PLUS® treatment consists of a highly revolutionary electrochemical treatment of less than O, 3 micron (millimeter of millimeter) nanoparticles and of a TOP SECRET substance deposition that can drastically lower the coefficient of friction of two connecting surfaces.

After the application

DURAFOSF PLUS® treatment creates a thin lubricating layer that can reduce to O, O1 the friction coefficient between two surfaces, a coefficient comparable to that one obtained by sliding two pieces of ice on each other.

This layer is completely dry and perfectly adheres to the surface.

Therefore it is to exclude a possible filth and contamination of the environment, such as in the case of oil or grease lubrication.

Benefits entailed

• It makes possible a dry and clean lubrication.

• It improves the break-in, even in combination with oil or grease lubrication.

• It protects against wear and, at low speeds, prevents the heave advancement.

• It allows a life-long lubrication at high and low temperatures, under the influence of fluids, before UV radiation or in vacuum conditions.

• Excellent corrosion protection.

• It facilitates the assembly and dismounting of coupling components with minimum tolerance values.

• In loosening couplings it ensures defined tightening torque and relative preload values.

• It makes possible economic solutions using targeted application procedures.

After the application

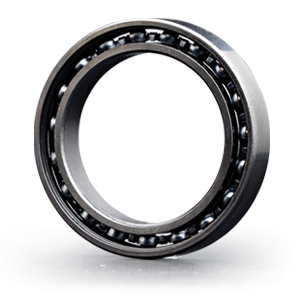

Other than the field of aerial and space navigation, DURAFOSF PLUS® is often used, to a large extent, in small but important components such as, for example, magnets, sliding bearings and bench studs, safety belt components (locking systems, rollers), hinges, screws and bolts, valves, pistons, deflection guides, gaskets, rolling bearings, guides, bushings, bronzes, ball bearings, chains and many moving parts ensuring a friction reduction of over 90%.

DURAFOSF PLUS and ADDITIVE OIL

An oil added with nanoparticle to further enhance and exalt the benefits in terms of performance and duration offered by the treatment itself, also accompanies DURAFOSF PLUS® treatment.

This lubricant is made of active, corrosion-resistant nanoparticles, intermittent loads, vibrations. It reduces noise, and makes non-stick treated surfaces.

Lubricant also offers greater protection against atmospheric agents by forming an invisible, dry to the touch film that obstructs the adhesion of contaminants on the mechanical members, preventing its operation.